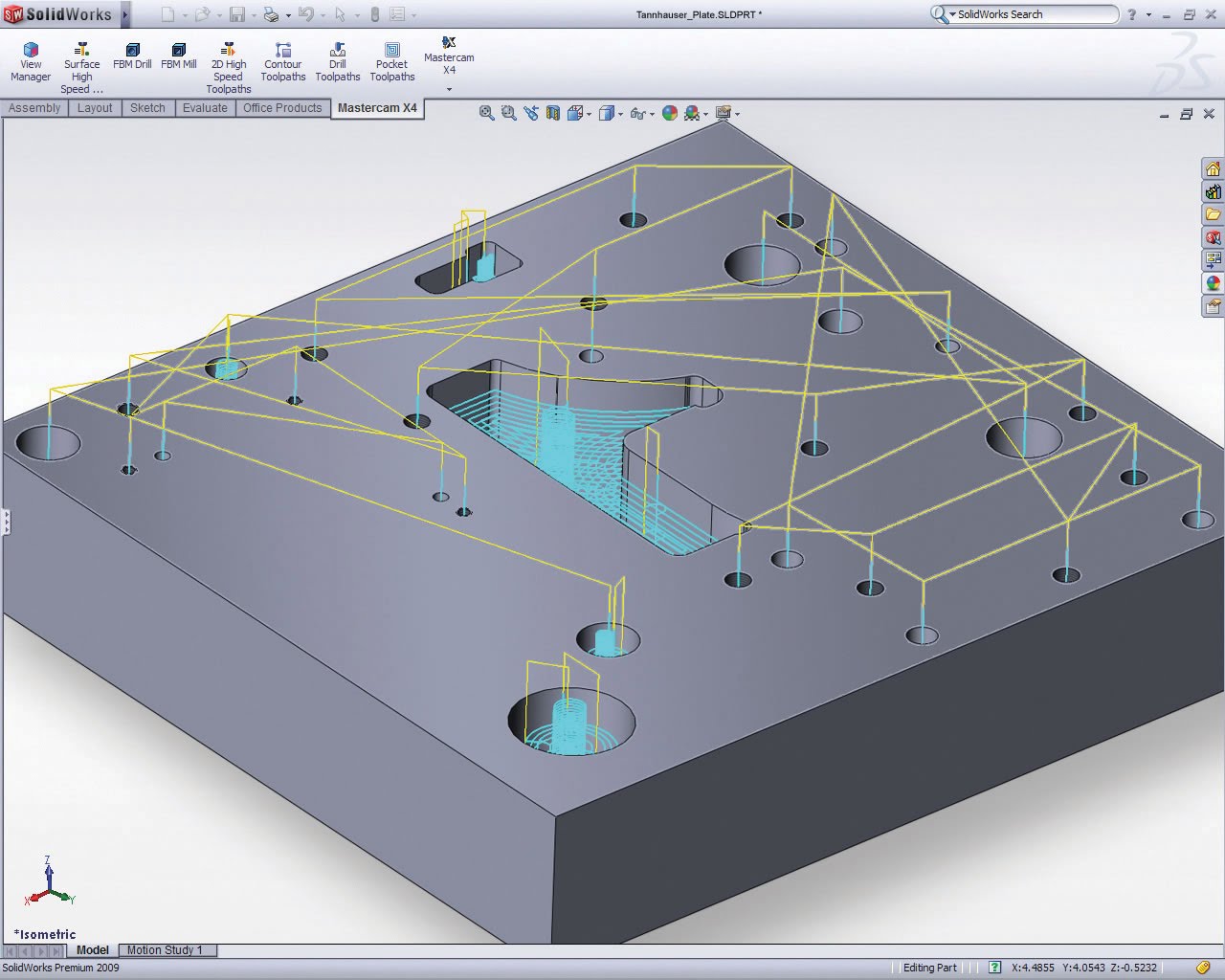

* The strategies “Basic selection” and “Cleaning the area” effectively remove the bulk of the allowance due to the use of toolpaths that are configured to “peel” the workpiece or “grow” the material from the cavities. Mastercam for SolidWorks includes a set of fully associative high-speed toolpaths to get the most out of your CNC equipment. High Speed Machining (HSM) provides the fastest processing technology and superior surface finish. The main haul effectively removes the bulk of the stock. Rough and finish 3D processing, including post-processing. * Recognition of holes and the creation of centering, drilling, reaming, chamfering, and threading operations according to specified criteria. * Roughing and finishing toolpaths for each pocket. * Processing open, nested and through pockets.

* Facing in case of detection of an allowance above the surface of the part. To perform 2D-3D machining, Mastercam for SolidWorks has the powerful feature of Feature Based Machining (FBM).īy analyzing a part for specific geometry features (surface, size, hole pattern, etc.), FBM automatically generates an efficient processing strategy for the recognized features.Īmong the main functions, the following should be noted:

Working with Mastercam 2023 (v5.10) for SolidWorks 2012-2022 fullĭescription: Efficient automated 2D-3D processing.

0 kommentar(er)

0 kommentar(er)